In the realm of high-end manufacturing, even the slightest leak can lead to product failure, safety hazards, and significant economic losses. Traditional leak detection methods are often like searching for a needle in a haystack. However, Helium Mass Spectrometry Leak Detection (HeMSLD) has become the gold standard for ensuring “absolute sealing” with its unparalleled precision and sensitivity.

Unique Advantages of Helium Mass Spectrometry Leak Detection

- Extraordinary Sensitivity: The detection capability of helium mass spectrometry far exceeds traditional methods, such as soap bubble tests or pressure decay tests. It can detect leaks as small as 10^-12 Pa·m³/s, equivalent to a leakage of just a few milliliters of gas per year.

- Precise Quantification: Beyond simply determining whether a leak exists, helium mass spectrometry can accurately measure the leakage rate, providing valuable data for product quality control and process improvement.

- High Safety: Helium is an inert gas, non-toxic, non-corrosive, and non-flammable, ensuring the safety of the entire detection process.

- Fast and Efficient: This technology significantly improves detection efficiency, quickly locates leaks, reduces production cycles, and minimizes rework costs.

How Helium Mass Spectrometry Leak Detection Works

The helium mass spectrometry leak detector operates through a series of precise steps:

- Injection of Helium: Helium or a helium gas mixture is introduced into the test object (e.g., battery packs, vacuum chambers).

- Pressure Difference Creation: At the same time, the external side of the object is evacuated, creating a pressure differential between the inside and outside.

- Helium Escape: If there is a leak, helium gas molecules escape through the hole due to the pressure differential.

- Helium Capture: The escaped helium gas is quickly captured by the leak detector’s efficient vacuum system.

- Ionization of Helium: In the mass spectrometer, an electron beam is directed at the gas molecules, causing the helium molecules (He) to lose electrons and form positively charged helium ions (He⁺).

- Helium Ion Selection: The helium ions are accelerated into a strong magnetic field. Due to their mass, the ions follow different paths, and those with a mass of 4 (helium) are precisely filtered through a narrow channel.

- Signal Interpretation: The filtered helium ions strike a detector, generating a weak electrical signal. This signal is amplified and processed by an electronic system, and the leakage rate is displayed clearly on the instrument’s screen.

Key Components of a Helium Mass Spectrometry Leak Detection System

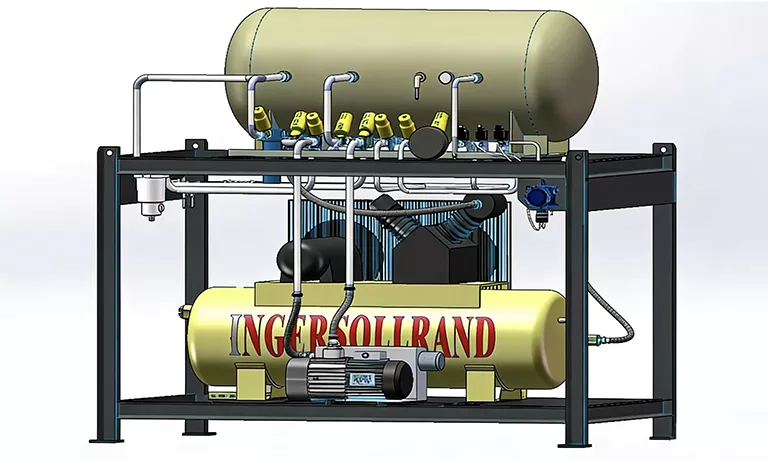

- Vacuum System: The core component, typically made up of a mechanical pump and a molecular pump (or turbomolecular pump) that maintains the necessary vacuum for mass spectrometric analysis.

- Mass Spectrometer: The “brain” and “heart” of the system, containing the ion source (ionization), analyzer (magnetic field separation), and ion detector (signal reception).

- Electrical Control System: The “nervous system” of the system, responsible for controlling the operation, precise parameter adjustments, signal amplification, and ensuring stable performance.

- Standard Leak Hole: A reference “scale” providing a known and constant leak rate for periodic calibration of the instrument, ensuring long-term accuracy and traceability.

- Human-Machine Interface: The operator’s interface, providing parameter settings, real-time leakage rate display, status monitoring, and result recording.

Application: Ensuring Sealing in High-End Manufacturing

- New Energy Vehicles: Leak testing for battery packs, battery casings, fuel cell stacks, and hydrogen tank valves, which directly impact safety and range.

- Refrigeration Industry: Leak detection for refrigerant lines, compressors, and automotive air conditioning systems, influencing energy efficiency and environmental impact.

- Semiconductor Manufacturing: Ensuring the gas tightness of chip packaging to prevent moisture and contaminants, safeguarding chip yield and lifespan.

- Vacuum Equipment: Maintaining ultra-high vacuum in vacuum coating machines, particle accelerators, and vacuum furnaces, which is critical for process success.

- Aerospace: Leak verification of satellite fuel tanks, spacecraft cabins, life support systems, and rocket engine components, ensuring mission success and astronaut safety.

- Medical Devices: Ensuring the lifelong sealing of implanted devices (e.g., pacemakers, neurostimulators), and maintaining vacuum in blood collection tubes.

- Scientific Research: Leak testing for complex ultra-high vacuum systems used in large particle colliders, nuclear fusion experiments (e.g., Tokamak), and other scientific facilities.

Value of Helium Mass Spectrometry Leak Detection

Helium mass spectrometry leak detection is not just a tool for quality control but also a strategic investment in a company’s core competitiveness:

- Building Quality and Reliability Barriers: It prevents performance degradation, functional failure, and safety hazards caused by leaks, thereby establishing a strong product reputation.

- Strengthening Safety Defenses: In energy, chemical, and medical sectors, it effectively prevents the leakage of flammable, explosive, toxic, or harmful gases, ensuring the safety of personnel, the environment, and assets.

- Driving Cost-Efficiency Win-Win: By early and accurately locating and repairing leaks, the technology reduces after-sales maintenance, recalls, and production waste, improving overall operational efficiency and product yield.

Helium mass spectrometry leak detection, with its scientifically rigorous principles, sophisticated instrumentation, and unrivaled detection capabilities, has become an essential technology for high-end manufacturing industries. It ensures the absolute sealing of products, safeguarding everything from microchips to spacecraft and contributing to sustainable development.