A detecção de vazamentos é amplamente utilizada na indústria, especialmente na gestão da segurança de gasodutos, dutos de líquidos e vasos de pressão. Com o desenvolvimento da ciência e da tecnologia, os métodos de detecção de vazamentos estão se tornando cada vez mais precisos e diversificados. O hélio tornou-se uma escolha ideal para a detecção de vazamentos devido às suas propriedades físicas e químicas únicas. Este artigo explorará as razões e vantagens do uso do hélio na detecção de vazamentos.

Características do hélio

O hélio é um gás inerte, incolor, inodoro e atóxico. Seu peso molecular é extremamente pequeno, apenas um quarto do do ar, o que o torna mais fácil de atravessar poros e aberturas minúsculas do que o ar. Portanto, apresenta sensibilidade e confiabilidade extremamente altas na detecção de vazamentos.

Além de seu baixo peso molecular, o hélio também apresenta baixíssima reatividade química. Ao contrário de outros gases, o hélio dificilmente reage com qualquer substância, o que o torna muito adequado para uso em ambientes complexos e não afeta os materiais dos objetos a serem testados nem altera suas propriedades.

Detecção de vazamentos de alta precisão

Tecnologia de detecção de vazamentos de hélio Possui sensibilidade extremamente alta e pode detectar vazamentos minúsculos. Comparado aos métodos tradicionais de detecção de vazamentos de gás, o hélio pode detectar vazamentos menores e mais ocultos. Isso ocorre porque as moléculas de hélio são muito pequenas e podem fluir rapidamente através de poros minúsculos, permitindo a detecção de até mesmo vazamentos minúsculos.

A detecção de vazamento de hélio geralmente utiliza dois métodos: um é o "teste de estanqueidade", que consiste em encher o objeto de teste com hélio e usar sensores externos para detectar se há vazamento de hélio; o outro é o "teste de vazamento externo", que consiste em injetar hélio no ambiente externo e usar detectores para detectar a fonte do vazamento. Ambos os métodos podem fornecer resultados de detecção de alta precisão para garantir que os problemas de vazamento possam ser descobertos e resolvidos a tempo.

Alta segurança

Como o hélio é um gás inerte e não reage quimicamente com outras substâncias, seu uso para detecção de vazamentos é extremamente seguro. Para equipamentos em ambientes de alta pressão e com produtos químicos complexos, a detecção de vazamentos com hélio é uma opção muito segura. Não terá nenhum impacto negativo na saúde dos funcionários, nos materiais dos equipamentos ou no ambiente operacional.

Comparado ao uso de outros gases, como nitrogênio, amônia ou cloro, para detecção, o hélio apresenta, sem dúvida, vantagens significativas em termos de segurança. Especialmente em alguns ambientes que envolvem gases inflamáveis e explosivos ou altas temperaturas, o uso de hélio pode reduzir efetivamente a ocorrência de acidentes.

Eficiente e rápido

As moléculas de hélio são pequenas e podem se difundir rapidamente, passando por pequenos orifícios de vazamento. O processo de detecção de vazamentos de hélio é muito rápido e permite determinar rapidamente a localização e o tamanho do vazamento. Isso melhora significativamente a eficiência da detecção, reduz o tempo de inatividade desnecessário e garante que potenciais riscos à segurança sejam resolvidos no menor tempo possível.

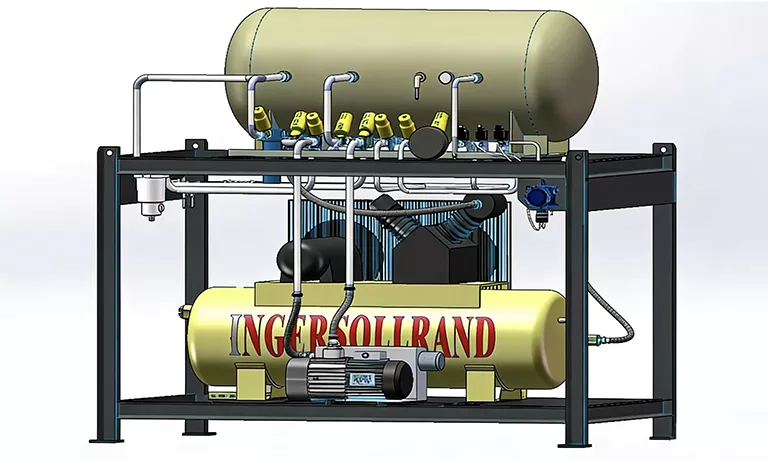

Além disso, equipamento de detecção de vazamento de hélio Geralmente, são equipados com sensores de alta precisão e sistemas de automação, o que aprimora ainda mais o nível de automação do processo de detecção. Mesmo em ambientes complexos, os operadores podem obter facilmente dados precisos e localizar rapidamente a origem do vazamento.

Amplamente utilizado

A tecnologia de detecção de vazamento de hélio é amplamente utilizada nas indústrias aeroespacial, automotiva, de equipamentos médicos, de semicondutores e de energia. Por exemplo, na indústria aeroespacial, a detecção de vazamento de hélio é usada para garantir a vedação de naves espaciais e garantir a estanqueidade em ambientes extremos; na indústria automotiva, o hélio é usado para detectar a vedação de airbags, pneus e outros componentes automotivos.

Além disso, o hélio também é amplamente utilizado na detecção de vazamentos em equipamentos de alta precisão, como reatores nucleares, sistemas de gases medicinais e sistemas de gases de ultra-alta pressão. Ao usar hélio para detecção de vazamentos, essas indústrias podem garantir a segurança e a confiabilidade dos equipamentos e evitar acidentes de segurança causados por vazamentos.

Conclusão

O hélio tornou-se uma ferramenta importante na detecção moderna de vazamentos devido às suas propriedades físicas e químicas únicas. Suas propriedades moleculares pequenas, inertes, atóxicas e inodoras o tornam a escolha ideal para detecção de vazamentos de alta precisão, alta eficiência e segurança. À medida que os requisitos de segurança, precisão e eficiência aumentam em diversos setores, a tecnologia de detecção de vazamentos com hélio será, sem dúvida, amplamente utilizada em mais áreas.