Grâce aux progrès constants de la science et de la technologie, les lignes de production automatisées sont progressivement devenues indispensables à l'industrie moderne. Dans le secteur manufacturier, en particulier, de plus en plus d'entreprises adoptent des technologies d'automatisation pour améliorer l'efficacité de la production et la qualité des produits, réduire les coûts de main-d'œuvre et répondre efficacement aux fluctuations de la demande. Les lignes de production automatisées sont non seulement le fruit de l'innovation technologique, mais aussi la clé du renforcement de la compétitivité des entreprises face à la concurrence mondiale.

Contenu principal:

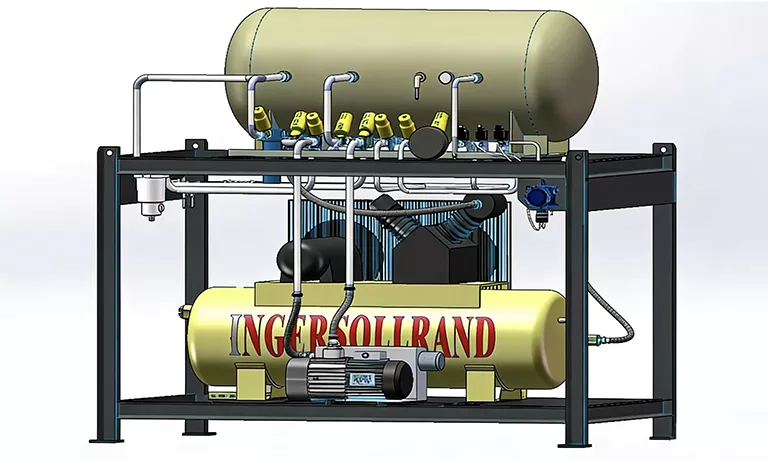

La ligne de production automatisée fait référence à l'introduction de équipement d'automatisation avancé et des systèmes de contrôle pour automatiser toutes les étapes du processus de production. Ces équipements comprennent des robots, des convoyeurs, des capteurs, des systèmes de contrôle informatisés, etc., qui interagissent pour assurer l'intégralité du processus de production, du traitement des matières premières à la livraison du produit fini.

Les avantages des lignes de production automatisées se reflètent dans de nombreux aspects :

Améliorer l'efficacité de la production : les équipements automatisés peuvent fonctionner en continu, sans interruption, améliorant ainsi considérablement l'efficacité opérationnelle de la ligne de production. Ils permettent un gain de temps considérable par rapport aux opérations manuelles traditionnelles et permettent de répondre à des besoins de production plus élevés.

Réduire les coûts de main-d’œuvre : en remplaçant les équipements automatisés, les entreprises peuvent réduire leur dépendance aux opérations manuelles et réduire les coûts associés tels que le recrutement, la formation et la gestion des employés.

Améliorer la qualité des produits : les lignes de production automatisées peuvent réaliser un contrôle précis et un fonctionnement cohérent, garantissant ainsi la stabilité et la haute cohérence de la qualité des produits et réduisant les fluctuations de qualité causées par le fonctionnement manuel.

Économisez de l'énergie et des matériaux : Le système automatisé peut optimiser chaque maillon du processus de production, réduire le gaspillage de ressources, améliorer l'efficacité énergétique et se conformer aux concepts de production modernes, verts et respectueux de l'environnement.

Forte flexibilité et adaptabilité : les lignes de production automatisées modernes ont une forte flexibilité et peuvent être rapidement ajustées en fonction des changements de la demande du marché pour produire différents types de produits, améliorant ainsi la compétitivité du marché des entreprises.

Conclusion controversée :

Bien que les lignes de production automatisées présentent des avantages significatifs en termes d'amélioration de l'efficacité et de réduction des coûts, elles présentent également certains défis. Par exemple, l'investissement initial en équipements est élevé, ce qui nécessite un soutien financier suffisant pour les entreprises ; parallèlement, la généralisation de l'automatisation peut également entraîner du chômage sur certains postes et engendrer des problèmes sociaux liés à l'emploi. Par conséquent, concilier progrès technologique et responsabilité sociale est devenu un problème complexe que de nombreuses entreprises et gouvernements doivent résoudre de toute urgence.

En bref, lignes de fabrication automatisées Les chaînes de production automatisées modifient progressivement le modèle de production traditionnel et jouent un rôle important dans la promotion du développement industriel et l'amélioration de la compétitivité des entreprises. À l'avenir, avec le développement continu des technologies et la popularisation des applications, les lignes de production automatisées ouvriront des perspectives plus larges.