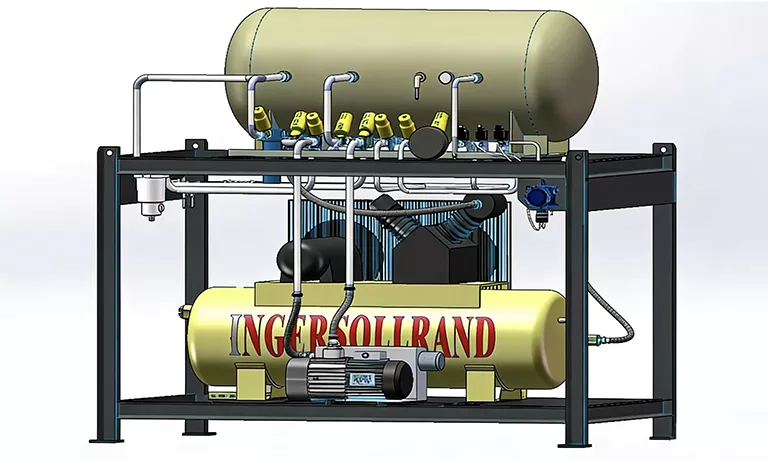

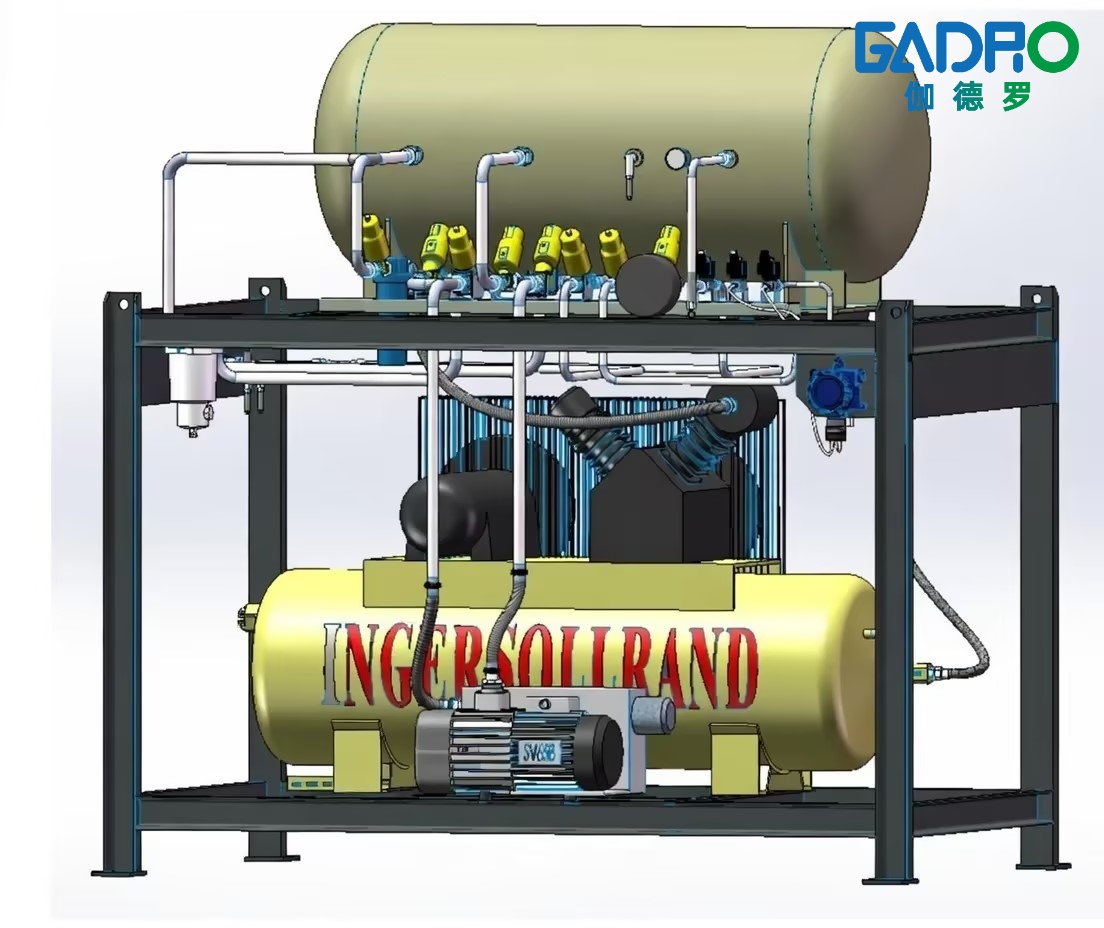

Helium Charging & Recovery System — Core Value in Helium Leak Detection

Gadro’s helium recovery systems are designed for diversified applications. The system automatically monitors the helium pressure and performs a compensation of pure helium once the helium pressure or concentration lower than set value. It collects helium from the test part, and can recover helium gas up to 98% which saves money, reduces waste, supports environment sustainability, improves production efficiency as well. It perfectly collaborates with helium mass spectrometer leak detectors, and is the core guarantee for the commercialization, scale and automation of leak detection processes in high-end manufacturing fields.

Core User Value

Cost Saving for Scarce Gas — Realize high-efficiency recovery (≥95%) and high-precision purification of high-purity helium, realize closed-loop recycling of helium, reduce the purchase of new helium by more than 70%, and fundamentally solve the high cost problem caused by helium emission in leak detection.

Efficient & Stable Leak Detection — Realize automatic linkage with leak detector, and complete the whole process of workpiece vacuuming, helium charging, pressure maintaining detection, helium recovery and pressure returning without manual intervention. Precise control of charging pressure and flow ensures the consistency of detection data and greatly shortens the beat of batch leak detection.

Safe & Compliant Operation — Adopt closed pipeline design to realize zero emission of helium in the whole process, avoid oxygen dilution and low temperature injury caused by helium accumulation in the workshop, and meet the environmental protection and on-site operation specifications of industrial production.

Flexible Adaptation to Scenarios — Modular design is suitable for leak detection of workpieces with different volumes, pressure grades and precision requirements. It can realize micro-precise charging of small parts and high-pressure large-flow charging and rapid recovery of large-volume workpieces, and the purified helium can meet the high-purity requirements of ultra-high vacuum leak detection.

System Synergy

As the process execution core matching the leak detector (detection core), the system solves the problems of “how to charge and recover helium” for leak detection, while the leak detector focuses on “identifying leak points and leak rates”. The integrated linkage of the two forms a complete industrial helium leak detection solution, which effectively guarantees the feasibility, economy and reliability of the leak detection process for users.