جدول المحتويات

In the world of industrial manufacturing, “Zero Defect” is not just a slogan; it is a requirement. For years, air pressure decay (differential pressure) has been the standard for leak testing due to its low cost and simplicity. However, as industries like automotive, HVAC, and medical devices demand tighter tolerances, air testing is reaching its physical limits.

If your production line is facing false rejects due to temperature changes or missed micro-leaks, it might be time to upgrade to a نظام كشف تسرب الهيليوم.

1. The Limit of Air Pressure Decay

Air pressure decay works by pressurizing a part and measuring the pressure drop over time. While effective for gross leaks, it struggles with micro-leaks (smaller than $1 \times 10^{-3}$ mbar·l/s).

Furthermore, air is sensitive. A slight change in ambient temperature or part expansion can cause pressure fluctuations, leading to “false failures” or, worse, passing a defective part.

2. Why Helium Changes the Game

Helium is the smallest inert gas molecule suitable for industrial testing. Unlike air, it does not react with parts and is unaffected by temperature changes.

- Superior Sensitivity: Helium systems can detect leaks as small as $1 \times 10^{-12}$ mbar·l/s. This is critical for parts that must hold gas or vacuum for years, such as airbag inflators or refrigeration compressors.

- Speed and Accuracy: Helium testing (especially the vacuum chamber method) is faster and provides a deterministic result. It tells you exactly how much is leaking, not just a pressure change.

3. Addressing the Cost Myth

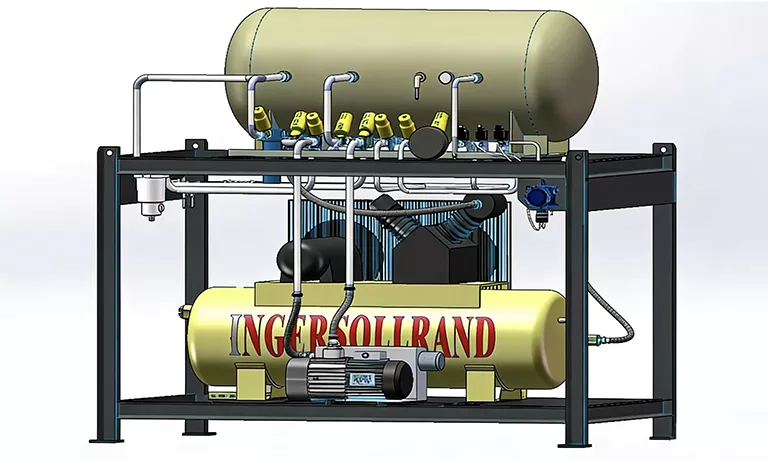

The biggest hesitation for manufacturers is the cost of helium gas. However, modern systems are equipped with helium recovery units. These systems capture and recycle up to 98% of the tracer gas used during testing. This drastically reduces operational costs, making helium testing an affordable solution for high-volume production.

خاتمة

Transitioning from air to helium is an investment in your brand’s reputation. It eliminates the guesswork of quality control.

[> Contact us today to compare the ROI of upgrading your leak test line.]

FAQ: Common Questions About Switching to Helium

Q1: Can helium leak detection be automated?

A: Yes. Our systems are designed for full integration into automated production lines (in-line testing), ensuring they meet your production cycle time (takt time).

Q2: Is helium gas dangerous to my workers?

A: No. Helium is an inert, non-toxic, and non-flammable gas. It is completely safe to use in an industrial environment.

Q3: How much more sensitive is helium compared to air testing?

A: Helium testing is typically 1,000 to 10,000 times more sensitive than air pressure decay, allowing you to detect leaks that air testing would completely miss.